Unlock Your Imagination: The Ultimate Guide to T-Shirt Screen Printing Success

Worldwide of t-shirt screen printing, the journey from idea to development is both elaborate and gratifying. Comprehending the fundamental strategies and tools is crucial for any individual looking to generate top quality designs that resonate with their target market. This guide aims to brighten the vital steps and best methods that can boost your screen printing endeavors. The course to success is not just concerning grasping the craft; it also includes calculated advertising to efficiently display your distinct offerings. What are the crucial insights that can change your approach to this creative procedure?

Recognizing Screen Printing Essential

Recognizing the principles of screen printing is crucial for anybody looking to develop top quality customized T-shirts. This versatile printing technique entails transferring ink via a mesh screen onto fabric, enabling vivid and long lasting layouts. The process starts with producing a stencil, called a display, which is created to obstruct out locations where ink need to not be used.

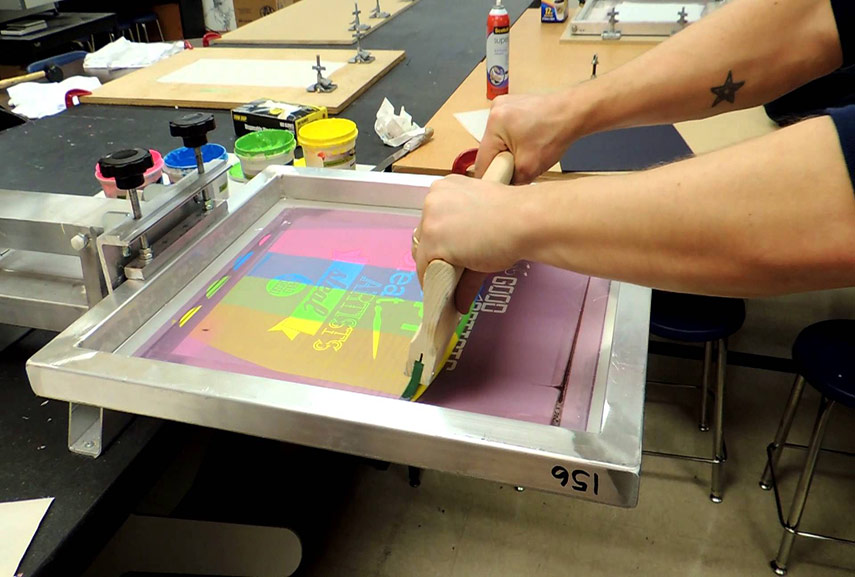

Once the screen is prepared, the material is located underneath it, and ink is pressed via the mesh making use of a squeegee - Texas Screen Printing Experts. This technique makes it possible for precise application and can fit various design and colors. The elegance of screen printing depends on its ability to produce huge amounts of constant prints, making it a prominent option for companies and events

In addition, comprehending the complexities of screen printing can greatly affect the end product. Elements such as ink thickness, mesh matter, and treating methods can influence the overall top quality and toughness of the print. By grasping these standard concepts, individuals can ensure their custom-made T-shirts not just meet visual assumptions but also stand the examination of time regarding wear and washability.

Crucial Products and Tools

To effectively perform screen printing, a selection of essential materials and devices is called for. At the structure of any screen printing setup is the screen itself, typically made of polyester mesh stretched over an aluminum or wood framework (T-Shirt Printing). This mesh holds the pattern that specifies the graphic to be printed

Next off, you will need a squeegee, a tool used to push ink via the screen onto the fabric. The kind of squeegee and its durometer (firmness) can impact the top quality of the print, so choose one suitable for your project.

Additional materials consist of solution and a light source for developing stencils, as well as tape for preventing and protecting the screen ink bleed. A work area equipped with cleaning products will promote correct maintenance of your tools and screens, ultimately boosting your printing effectiveness.

Creating Your T-Shirt Graphics

Creating compelling graphics for your T-shirts is a basic action in the screen printing process. The layout needs to not just record focus yet likewise share a message or motif effectively. Begin by brainstorming ideas that reverberate with your target market. Think about present patterns, cultural recommendations, or personal experiences that can inspire distinct styles.

Use design software application such as Adobe Illustrator or CorelDRAW to bring your principles to life. Take notice of shade theory; choosing the right scheme can significantly impact the total charm of your graphics. Screen Printing. Verify that your style is high-resolution, preferably 300 DPI, to preserve quality when printed

Assume regarding the positioning of your graphics on the Tees. Common areas consist of the front facility, back, or sleeves. Each placement has its own visual impact, so select carefully based upon your style and target market. In addition, think about the kind of ink and material you will be making use of, as these can affect the final look of your graphics.

Preparing Your Screens

Preparation is crucial for achieving top notch screen prints - T-Shirt Printing. The process starts with picking the appropriate mesh screen, as the mesh count directly influences the information and quality of your prints. A finer mesh matter appropriates for detailed styles, while a coarser count works best for strong graphics

Next off, make particular that your displays are clean and complimentary from any type of impurities. Dirt, oil, or remaining emulsion can compromise print high quality. Utilize a degreasing service to thoroughly clean the displays prior to using the solution.

Using the emulsion evenly is vital, as any kind of variances can cause unwanted blemishes in the last print. Use an inside story coater for a smooth, consistent layer, and enable enough time for drying in a dark environment to stay clear of direct exposure to light.

Once completely dry, it's time to reveal your screens using a light. Comply with the producer's standards for exposure times to accomplish the most effective results. After exposure, wash out the displays thoroughly to disclose your style, making certain that the areas meant to print are clear. Correctly prepared screens will certainly set the structure for an effective printing procedure, improving the total top quality of your t-shirt styles.

The Printing Process Explained

Understanding the printing process is crucial for accomplishing premium results in screen printing - Abilene T-Shirt Screen Printing Company. This area will cover vital components consisting of effective screen preparation methods, various ink application methods, and the essential curing and ending up actions. Each of these components plays a significant role in the overall success of the printing project

Screen Preparation Methods

Reliable screen preparation is crucial for attaining top notch prints in the screen printing process. The success of your prints greatly relies on the thorough preparation of the screen, which serves as the foundation for your layout.

Start with choosing a proper screen mesh, as the mesh matter affects the detail and opacity of your prints. A higher mesh count is ideal for complex styles, while a reduced matter is ideal for bold graphics. Next off, effectively degrease the screen to eliminate any pollutants that could affect attachment. This step guarantees that the solution adheres uniformly to the screen surface.

After degreasing, apply a light-sensitive emulsion making use of a scoop coater, making certain an uniform layer throughout the screen. Exposure to light will certainly solidify the solution where it is not covered by your layout, so it is critical to use a well-contrasted openness film for ideal results. Post-exposure, wash out the unexposed emulsion, revealing the pattern for your design.

Ink Application Techniques

Accuracy in ink application is crucial for attaining consistent and vivid results in the screen printing process. Various approaches can be used to use ink effectively, each with unique benefits depending upon the design and fabric kind.

The most common strategy is using a squeegee, which uniformly disperses ink across the screen to transfer the layout onto the substrate. The pressure and angle at which the squeegee is held can substantially affect the ink's density and quality. For in-depth or elaborate layouts, a better mesh screen can be made use of, permitting a lot more accurate ink application.

One more method is flood covering, where a layer of ink is very first spread throughout the screen prior to the real printing stroke. This method guarantees a consistent ink flow and decreases the threat of smudging or uneven application.

For sure applications, specialty devices such as rollers or spray weapons might be employed, offering added flexibility. Each approach requires ability and method to master, however understanding the subtleties of ink application can incredibly improve the top quality of your screen printing work, resulting in durable and lively prints on your T-shirts.

Curing and Completing Actions

When the ink has been applied to the Tee shirts, the following stage in the screen printing process entails treating and finishing the prints to validate toughness and quality. Healing is the essential step that ensures the ink sticks effectively to the fabric, stopping fading or peeling off during putting on and washing. This is normally achieved through warmth, where the published t-shirts are subjected to a specific temperature for a set duration, permitting the ink to bond with the fibers.

There are a number of techniques of healing, with one of the most common being using a conveyor dryer or a heat press. Conveyor dryers provide consistent heat and are appropriate for bigger batches, while warmth presses are suitable for smaller sized runs or specialized things. It is essential to monitor the temperature level and time accurately, as insufficient healing can bring about endangered prints.

Finishing steps may consist of quality checks for print imperfections, cutting excess strings, or folding and product packaging the shirts for delivery. Implementing these treating and completing procedures not only boosts the durability of the prints but likewise contributes to the total specialist look of the last product, important for consumer contentment.

Treating and Finishing Your Prints

Treating and completing your prints is an important action in the screen printing process, as it ensures the durability and vibrancy of the style. Recognizing efficient healing strategies can substantially influence the end product, while resolving common issues during this stage can enhance total quality. This area will check out the importance of correct curing, different finishing techniques, and just how to troubleshoot frequent challenges.

Relevance of Correct Curing

Ensuring correct healing is important for attaining high-quality screen prints that are long lasting and aesthetically appealing. Curing describes the process of applying warmth to the published ink, which triggers chemical responses that strengthen the ink onto the material. This step is crucial for making certain that the ink sticks efficiently, avoiding issues such as breaking, fading, or peeling with time.

The curing process differs depending upon the sort of ink made use of; plastisol inks, for example, usually call for a temperature of around 320 ° F(160 ° C) for appropriate healing. Insufficient this website curing can cause a variety of problems, consisting of inadequate clean durability, which might result in the print wearing away after just a few washes.

In addition, correct curing boosts the vibrancy of the print shades, guaranteeing that designs preserve their intended appearance. It is crucial to check the healing temperature level and time properly, making use of trustworthy tools such as a heat press or conveyor dryer.

Techniques for Effective Completing

Three essential methods can greatly improve the finishing procedure of screen-printed T-shirts, assuring both longevity and aesthetic appeal. Effective curing is paramount. Making use of a trusted warm source, such as a conveyor clothes dryer or warm press, warranties that the ink reaches the proper temperature. This not just sets the ink however additionally improves bond to the material, causing a long-lasting print.

Second, correct washing and drying out methods contribute substantially to the finishing high quality. After curing, enable the T-shirts to cool down appropriately prior to handling. When washing, select chilly water and moderate detergents to preserve the vibrancy of the colors. Air drying out is more suitable, as it reduces the danger of heat damages from clothes dryers.

Finally, think about post-curing therapies. Applying a heat press for a couple of seconds after the preliminary healing can further boost the ink's durability and offer a smoother finish. In addition, integrating finishing sprays or conditioners can enhance the responsive feeling of the fabric, boosting the total high quality of the Tee shirts. By implementing these techniques, you can accomplish a specialist standard in your screen-printed styles, contributing to client satisfaction and repeat organization.

Repairing Usual Concerns

Despite having proper techniques in position, issues can still arise during the curing and ending up stages of screen printing. One typical trouble is insufficient curing, which can cause prints that wash out or fade promptly. To resolve this, verify your healing temperature matches the producer's specs for the ink being used, commonly around 320 ° F (160 ° C) Utilize a reputable heat resource, like a conveyor clothes dryer, and verify the temperature with a warm weapon.

One more concern is under-exposure throughout the printing process, which can cause bad adhesion and splitting. To troubleshoot this, examine your direct exposure times and readjust based upon the certain solution and source of light.

Additionally, irregular finishes can occur as a result of improper application of the completing spray or excessive ink application. To treat this, use a constant layer of spray and validate that your squeegee technique is uniform.

Finally, constantly enable ample time for prints to cool before dealing with. This lowers the risk of smudging and verifies the stability of the layout. By adhering to these standards, you can successfully boost the top quality and repair of your screen-printed designs

Tips for Advertising Your T-Shirts

Effectively marketing your t-shirts requires a blend of creativity and calculated preparation. Begin by determining your target market; understanding their choices will assist your style and marketing efforts. Use social networks systems to display your developments. Involving visuals and engaging storytelling can assist establish a brand name identification that reverberates with potential customers.

Take advantage of influencer partnerships to expand your reach. Collaborating with individuals who line up with your brand name values can lend reputation and attract new fans. Furthermore, think about running targeted advertisements on systems like Facebook and Instagram to reach a wider audience, ensuring to tailor your messaging based upon demographic understandings.

Do not ignore the power of neighborhood events and pop-up stores. Taking part in area markets or fairs permits you to link directly with consumers and develop brand loyalty. Offer limited-edition layouts or exclusive offers to develop necessity.

Often Asked Concerns

Exactly how Do I Choose the Right Fabric for Screen Printing?

Selecting the appropriate textile for screen printing includes thinking about variables such as weight, texture, and absorbency. Cotton blends are optimal for lively prints, while synthetic fabrics provide toughness. Select materials suitable with your ink type for best outcomes.

Can I Publish on Colored or Dark Tee Shirts?

Yes, you can publish on colored or dark t-shirts. It is essential to make use of specialized inks, such as plastisol or discharge inks, which supply sufficient opacity to assure dynamic and enduring layouts on darker fabrics.

What Is the very best Means to Shop My Screens?

To guarantee long life and height efficiency, shop your displays flat in an amazing, completely dry environment, away from direct sunshine. Usage protective covers to avoid dust build-up and prevent piling to stop damage to the emulsion.

How Commonly Should I Tidy My Screens?

Regular cleaning of screens is vital to maintain print quality and longevity. It is advisable to clean displays right away after usage, making certain the removal of ink and emulsion, thereby protecting against build-up and maintaining peak efficiency.

What Prevail Mistakes to Avoid in Screen Printing?

Usual blunders in screen printing consist of inappropriate screen stress, insufficient ink blending, overlooking to tidy displays completely, wrong exposure times, and falling short to perform test prints. Each of these can greatly influence the end product's quality.

At the structure of any kind of screen printing setup is the screen itself, normally made of polyester mesh stretched over an aluminum or wooden frame. Efficient screen preparation is crucial for achieving top quality prints in the screen printing process. Accuracy in ink application is crucial for accomplishing vivid and constant results in the screen printing process. Once the ink has actually been used to the Tee shirts, the following phase in the screen printing process involves treating and ending up the prints to validate sturdiness and high quality. Common errors in screen printing consist of incorrect screen stress, poor ink blending, overlooking to clean displays thoroughly, inaccurate direct exposure times, and falling short to perform test prints.